Design tips vol. 4

I’ve been flat out on contracts and there’s no sign of slowing down. I have two more in-depth articles coming up about lubrication and fasteners but they need a bit more research so in the meantime, here’s some more design tips.

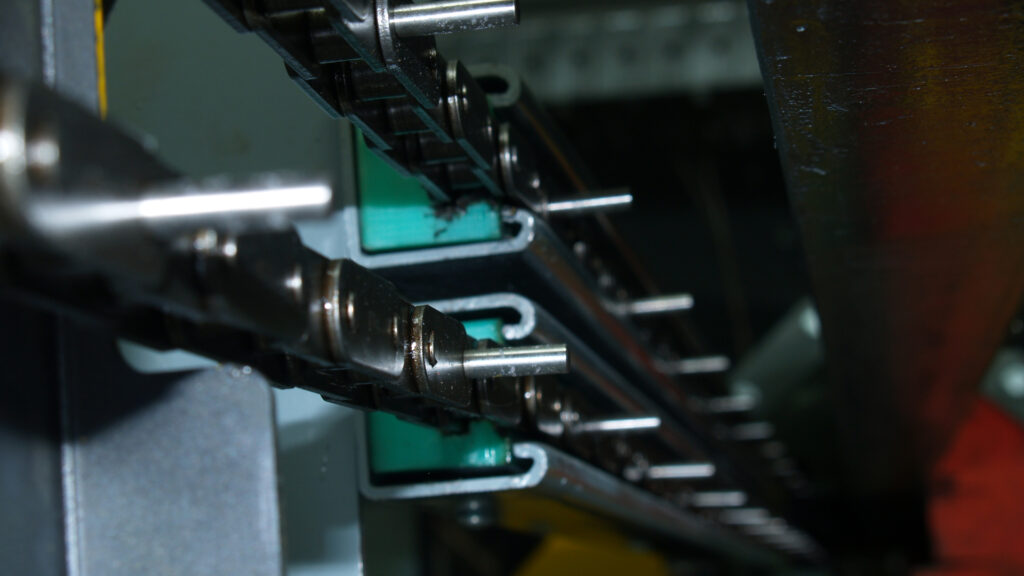

Roller chains are versatile

Roller chain is becoming less and less common in industrial applications because belts are generally quieter, cheaper and don’t require lubrication. The downside is belts require replacement more often but that’s a customer problem, not a designer problem so it isn’t often considered but I digress. There are some unconventional ways to make use of drive chains that you might not pick up on unless you peruse the design manuals. For example, attachment chains are quite expensive but you can order chains with extended drive pins. I’ve included an image below.

Vacuum formed parts

Vacuum forming is another “underdog” process in my opinion, much like steel rule die cutting which I mentioned in an earlier article. You can make the tool by CNC routing MDF and your local supplier can churn out parts at a very low per-piece cost.

Elesa ganter and Comac parts

If you’re making machining drawings for anything resembling a handle, you’re probably doing it the hard way. Homebrew machine elements are more expensive and generally don’t look as nice as bought once. Have a good look through the Elesa Ganter’s range of control knobs, handwheels, indexing plungers and so on. For lower cost versions, go to Comac. They both have CAD files of everything in their product range which is the first thing I typically look for.

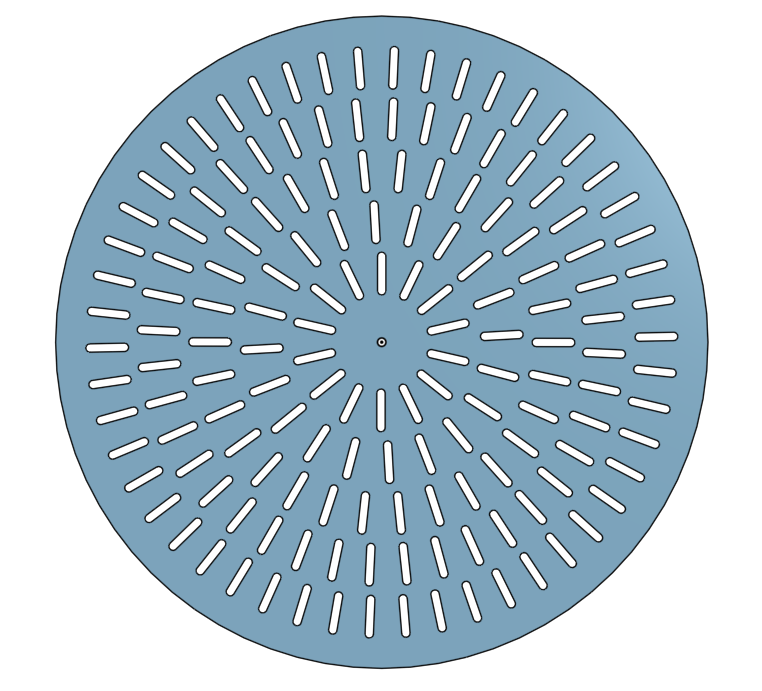

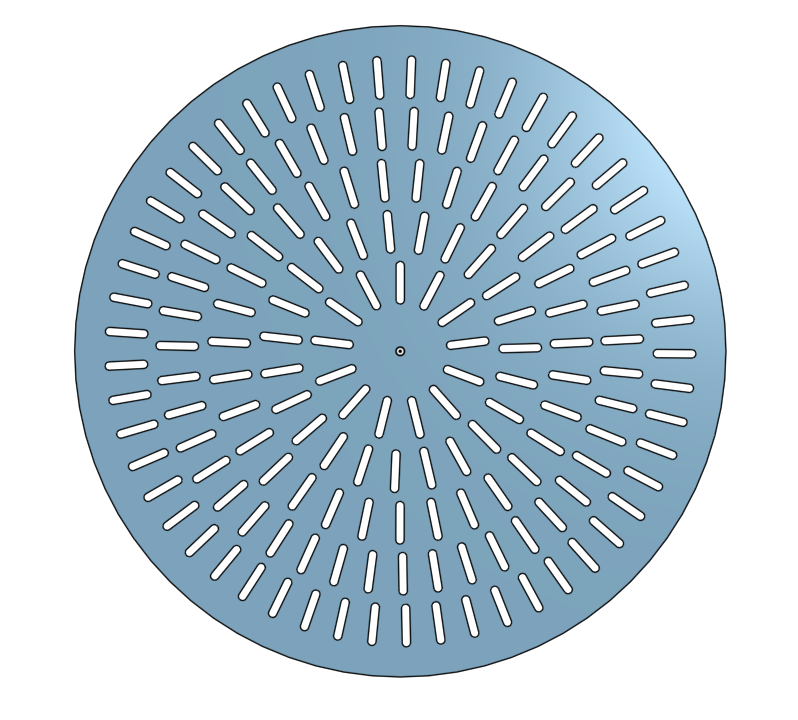

Prime numbers and drain holes

Look at the two grates below and decide instinctively which one looks better.

Oftentimes you need to draw up circular patterns of holes and slots. Things like drain holes, grids, vents, etc. It can be harder than you think. If you have an inner pattern of 10 elements and another concentric pattern around it, you’ll likely find that having 10 elements in the outer pattern is too sparse and 20 elements is too tight. So you can’t have spacing that is consistent as well as being equally “dense.” So you have to split the difference somehow and this results in elements not lining up. Which is fine but when some of them line up and some don’t it looks bad. The solution is to use prime numbers. Now nothing lines up which looks better than some things lining up.

It’s hard to describe in words so go back and look at the two grates. The image on the left has 14 elements on the innermost ring, then 20, 30, 40 and 50. On the right, the patterns are 13, 23, 31, 43 and 53. The difference is subtle but noticeable. The design on the left looks slightly awkward and the one on the right looks nicer.

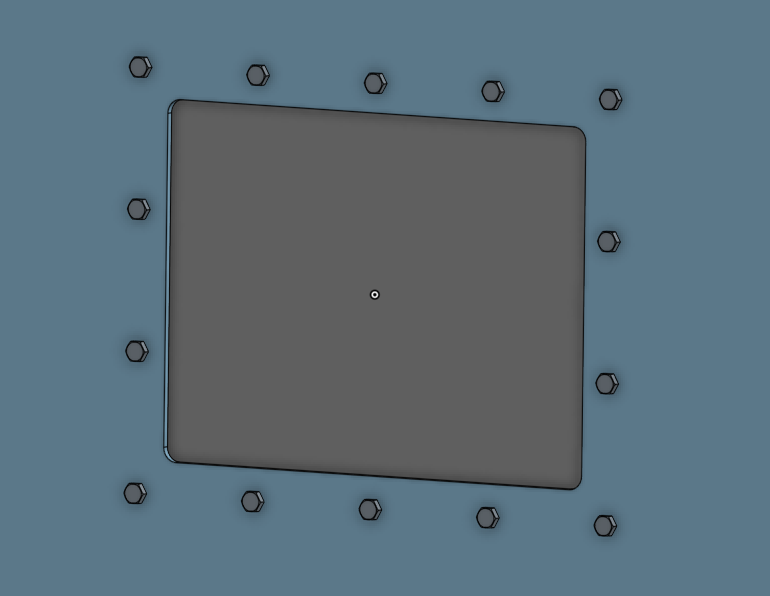

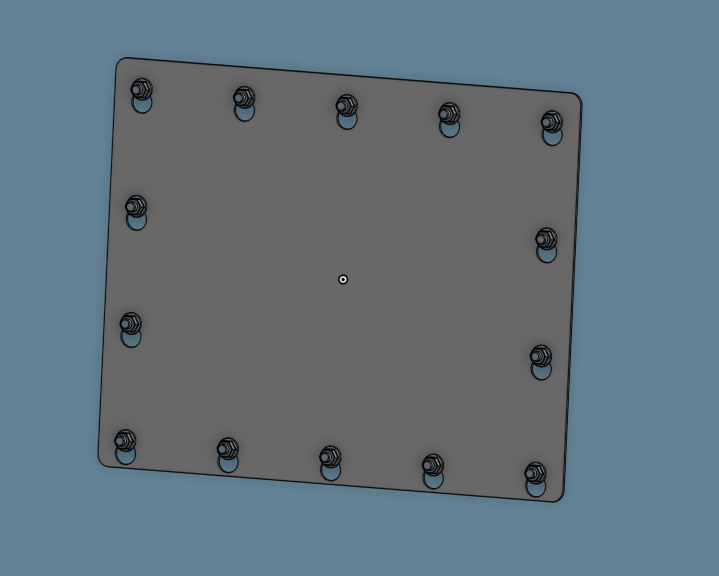

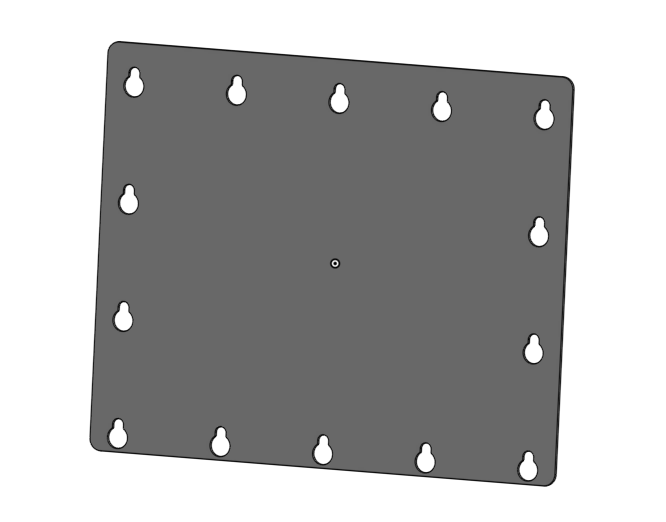

Cover plates

Oftentimes you need to make cover plates for your parts. First instinct is of course to tap holes in the base part and bolt through holes in the cover plate. But there’s sometimes other ways you should consider. For example, if you end up with a lot of threaded holes, consider a threaded insert. I know, they are terrible and always end up spinning. But these ones have an external hex which you can laser cut a hex shaped hole for. They won’t spin.

If the cover plate is big and heavy, it’s much easier to install if there’s a threaded stud on the base part so you can hang the cover on first and tighten fasteners. You can make it look extra nice by using dome nuts. But studs are expensive and painful- So we won’t actually use them. Instead, we just put a bolt through from the back and tack weld the head down. We’ll ignore every rule that we are breaking here- welding through zinc plating, welding fasteners, flagrant disregard of manufacturer’s instructions and downright cheek- Remember, it’s only a cover plate.

If fast removal is your goal, you can cut a keyhole shape in the cover plate so you only have to loosen the nut. It looks a bit ugly but this matters less than an unlubricated critical bearing so sometimes we compromise.

If keyholed studs is too slow and ugly, remember I just put a link to Comac above. A cover plate like this is a great candidate for a compression latch and a hinge. A final note on cover plates- They don’t have to be steel. I’m a huge fan of clear plastic covers where possible. You can strobe and visually inspect chains, belts, bearings and gearboxes without removing them.

That’s all for now, thanks for reading. I’ve not found any other use for prime numbers in my designs so if anyone out there has one, by all means, leave a comment.