The Mentaculus

When I first started my career in engineering, designing was done in AutoCAD, in 2D from hand-sketched layouts from the chief engineer. Design verification calculations were done manually (ie electronically but using calculators and Excel) and the mass of a weldment was estimated with the help of photocopied tables of per-metre section masses and per-square-metre masses of common sheet thicknesses. On my first day, I received a folder of such photocopies as well as other helpful information like a tables of limits and fits, common available hollow bar and bright steel sizes and so on. Everyone in the company had one of these folders. When I moved on, I sorely missed that folder and started to build my own.

Fast forward a decade or so and I had an electronic spreadsheet with tables of structural sections and steel size tables so I didn’t have to keep a physical folder. I found I had to do some calculations often, so I kept them in there, too. Every time I needed to do a new calculation that took me more than 10 minutes, I wrote it up into the spreadsheet- not on company time- it was for me. Also, any time I needed some technical information from a supplier that turned out to be difficult to find, that went in there, too.

The spreadsheet got larger and larger, and I started calling it the Mentaculus- a reference to a film called A Serious Man by the Coen Brothers. In the film, the Mentaculus is the scribbled gibberish of a presumably mentally ill physicist. At least, it appears to be gibberish- it really seemed to mean something to the character. It seemed fitting.

I take a copy of the Mentaculus wherever I go and it saves me a lot of time because it’s tailored to me and cross linked. The following is a quick rundown of what I’ve included which you may like to use as a basis to build your own:

Tables of available materials from your local suppliers

Available sizes, dimensions, masses, cross sectional areas and 4th moments of inertia (as appropriate) for:

- Structural steel sections (RHS, Beam, PFC, etc)

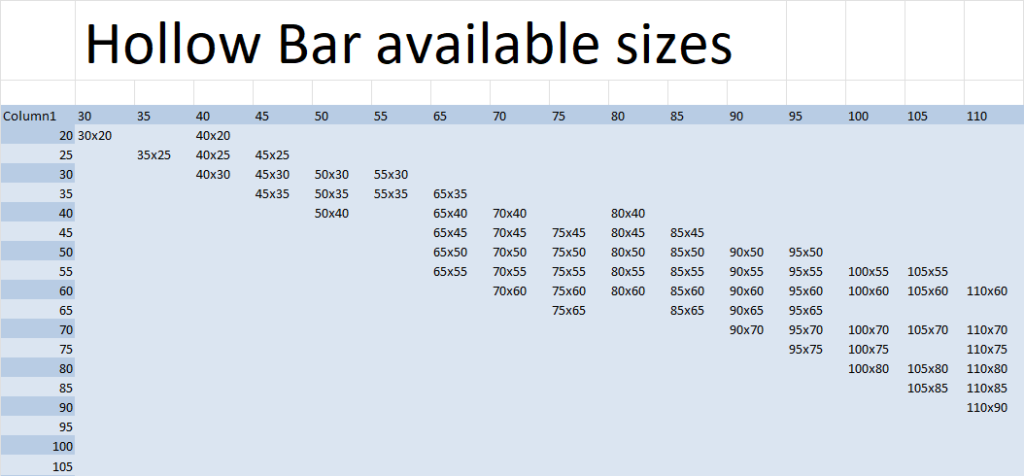

- Hollow bar

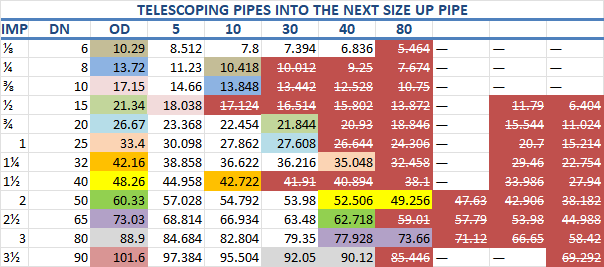

- Nominal pipe (for all schedules and which sizes can telescope in to what)

- Bright steel

- Perforated plate and mesh

- Strengths of various grades of various materials (and sometimes at various temperatures)

Data tables for products you use often

- Fittings (I have a rundown on thread standards like BSP, NPT, JIC, etc including what sizes of NPT and BSP you can fit together even though we all know we should never but we always will when the chips are down and it’s 5pm and everyone is closed)

- Fasteners and thread data tables (RIP Maryland Metrics, your company is no more but you will surely go to Engineering Heaven for your contribution to the world)

- Common springs and belleville washers

- Bronze bushes- protip, every manufacturer in the world seems to be using the Shorlube catalogue as an instruction manual)

- Steel cable

- Cable glands

- Sprockets

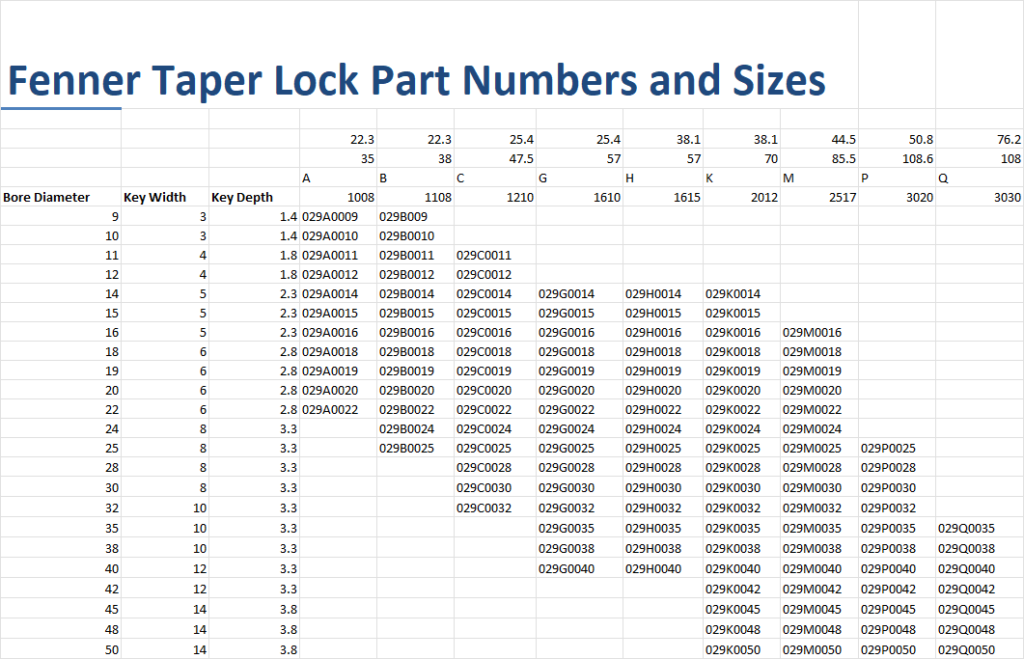

- Taperlocks

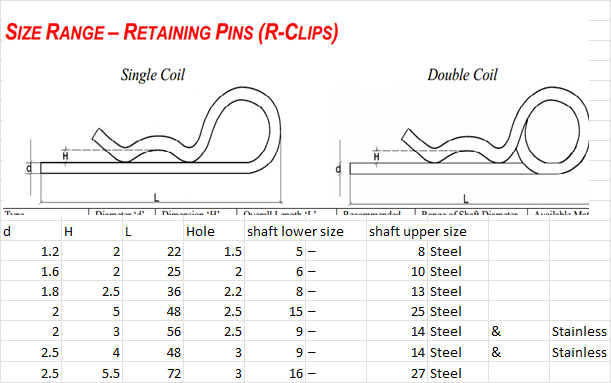

- R-clips

Common calculations

This is where efficiencies really multiple. For example, I have a bunch of automated simple beam equations and I can link the 4th moment of area and cross section areas to the structural steel tables from my local suppliers. If I am thinking of suspending a load from the middle of a beam, I can check 10 common available structural sections for suitability in less then a minute!

- Simple beam equations

- Euler buckling and bending stress calculations

- Go, No-go gauges

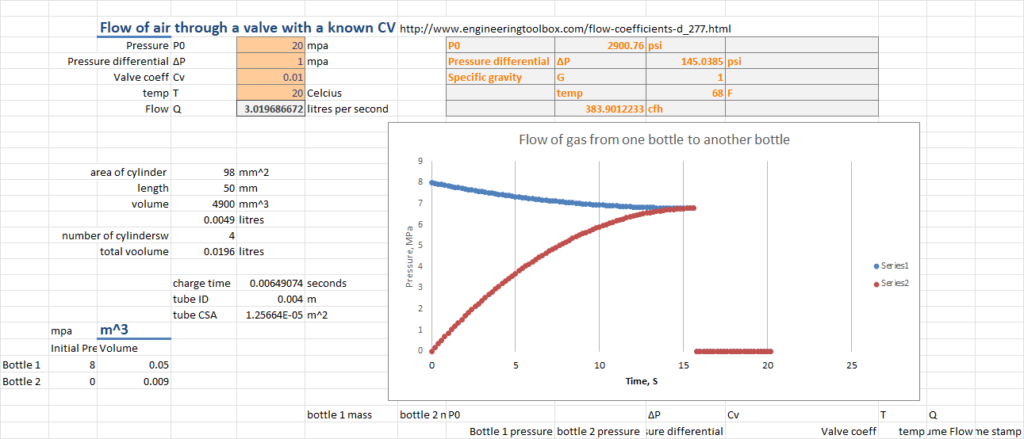

- Air flow calcs

- Gas strut calcs

- Tension, compression, torsion and disc spring (belleville washer) calcs

- Pressure vessels and vacuum vessels

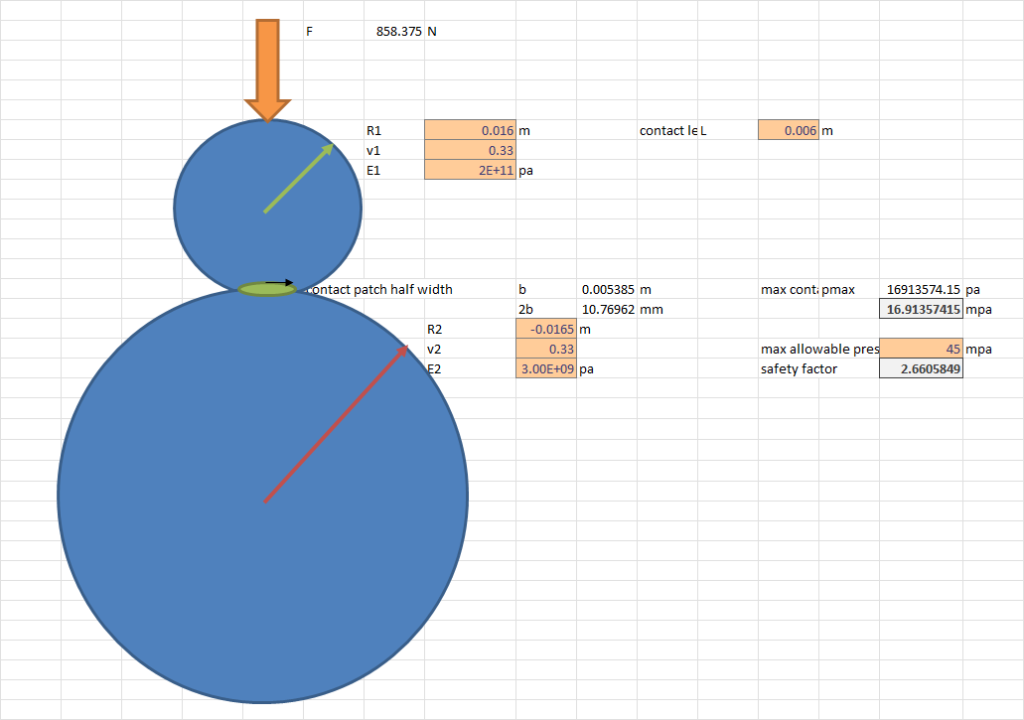

- Hertzian stress

- Vibration isolation and frequency response

- Insulated pipe and furnace thermodynamic calcs

- Mass flow from one fixed volume to another

Machine element and general design information

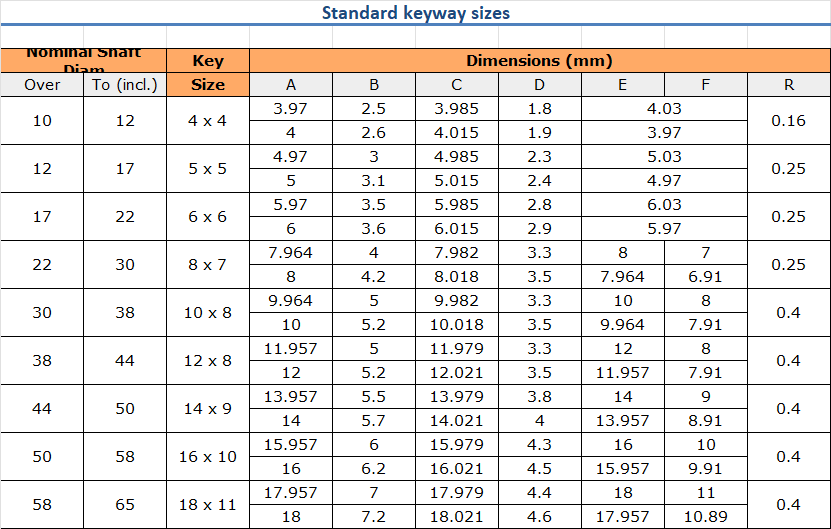

- Standard keyway dimensions

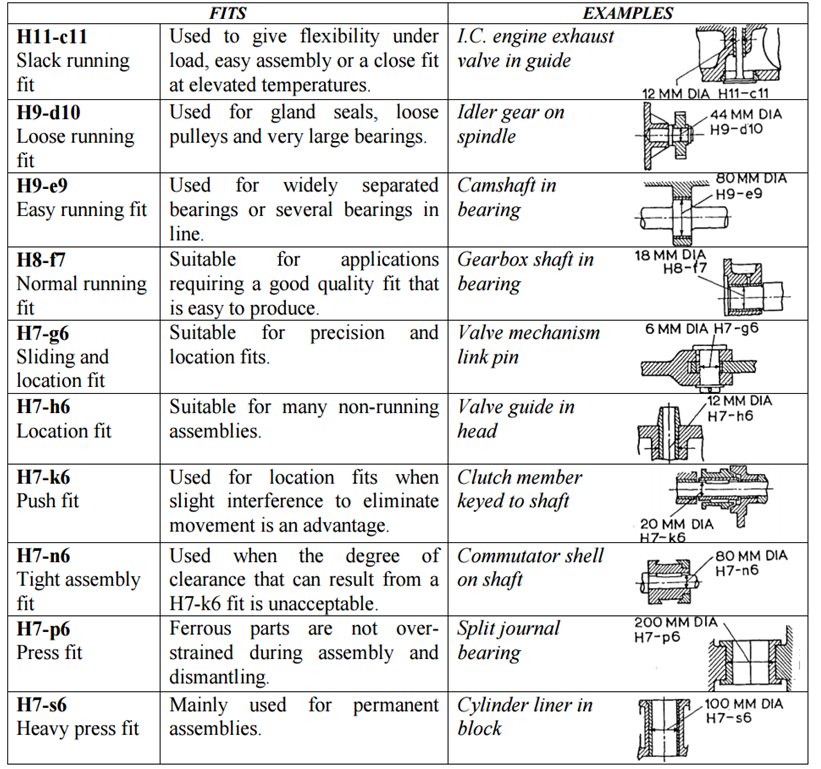

- ISO limits and fits

- Roughness tables

- Lifting lug dimensions

- Snap fit designs and relevant calcs

- Common locally available end mill sizes

Anything you damn well please. It’s your document.

- Any other tips and info that I have had trouble getting out of suppliers in the past

- Weld symbol explanations

- How much does hard anodizing grow a part?

- How much does a bearing bore in EN36A close up when heat treating?

- A very finely graded table of metric-imperial equivalents

…and so on…

Was it worth it?

A hundred times, yes. It’s like compound interest for engineers. The seconds add up. Something that really can speed you up as a designer is the ability to very quickly spitball a few ideas, know what works and what won’t and then go down the path to a finalised design with confidence and without further hesitation. The Mentaculus facilitates this.

I said earlier that I take a copy with me wherever I go. I leave a copy, too, in the hopes that it will seed other documents for other engineers to take around with them. If I hadn’t received a folder full of tables on my first day of work, the Mentaculus may not exist.

So next time you find yourself reading from a table on the internet or calculating stress = my / I for the fiftieth time, start your Mentaculus and never solve the same problem twice again.