What should you include in your machine manuals?

When I worked as a project engineer, it was hard to know exactly what a customer wanted out of a manual. If I supply a huge spare parts list, am I just wasting paper? If I use our own part numbers, will it seem like I’m trying to do a cash grab? If I make a list of all bearings that need to be greased, is that condescending? If I include information on how to do a full setup from scratch, will that confuse their operators? Will I endanger my IP if I include assembly drawings?

Having worked in maintenance for some time, my frustration over having not enough information trumped all of the previous concerns. Often times, you won’t have the time or resources or even permission to make a fully complete manual but having worked on the other side of the customer/supplier fence, please consider the below to be a wishlist from me, the guy who has to deal with the machine that you have supplied.

Machine serial and hotline info

Not many people have a full time support hotline but if you do, put this at the front in large font that can be read without glasses in the dark while in a panic. Having the machine serial number on the same page would be great.

Spares list

This should include all the obvious candidates for failure including gearboxes, bearings, belts, chains, heating elements, filters, pneumatic cylinders, solenoid valves. Some not-so-obvious candidates are:

- The pulleys that the belts are running on- they pulleys wear out faster than you’d think.

- Sprockets- it’s not just the chain that wears

- Any shaft that a bearing is on. If a bearing fails, it often destroys the shaft, too.

- Anything hard- knives, cams, wear plates, gears. They are usually hard so they wear

- Anything soft- rubber, plastic. They are usually soft because they are either gripping or rubbing on something.

- PLCs and VFDs. The lead times on some of these, particularly during covid exceeded six months.

Having a spares list with an OEM part number is a super nice thing to do for a customer but you’re well within your right to only supply your own part number and make me buy at least one. Don’t get me wrong, I’d love to have the SKF part number for all the bearings used but I’d rather have them named “cynical-cashgrab-5” than not have them at all. To a maintenance engineer, just the knowledge that a bearing exists in a particular subassembly is useful.

But I’d go further than a spares list if possible…

Spares list Parts list

Having a full parts list is so much better. A machined casting or a weldment is rarely considered a spare by anyone but if one breaks, it’s pretty nice to be able to go back to the manufacturer and say can I please get a quote for “shouldn’t-be-a-spare-part-001.” Again, I used to have concerns about IP with this kind of thing but what IP can really be gained by knowing that there are five castings in an assembly? That kind of information is really only useful to someone who’s just broken one and wants a replacement.

Drawings

Going further, if you weren’t involved in the machine design, parts lists can be pretty difficult to deal with in isolation. If you have drawings of the major assemblies in the plant that you can correlate to the parts list, so much the better. Paper-only is OK, PDF is better. Solid model would be dandy but you can’t really supply that without giving away too much information.

Having worked in machine design and manufacture, I know that follow-up spare parts sales are crucial to keeping a steady supply of sales coming in. Having now also worked in maintenance, I know that I squandered so many sales opportunities by being paranoid about IP and supplying, without drawings, only a list of parts that I considered to be perishable spares. If maintenance have to pull an assembly apart to know exactly what bearings are in it, they’ll have the bearing manufacturer’s part number and will buy it from them, not you.

Drawings list

This is useless until the customer starts to lose drawings at which point it becomes quite handy so they can ask for a replacement. And you can give it to them (for a price!)

Electrical stuff

Electrical equipment has a few special requirements:

Drawings

This is a no-brainer. Must be supplied- I’ve never not had it. Troubleshooting any major issue with no wiring diagram is incredibly difficult.

Electrical parts list

An electrical parts list is rarely supplied but can be very handy. It makes it much easier for the customer to know what contactors, fuses, motor controllers, etc, they should keep spare. It seems like it wouldn’t add much value to have it written down but traipsing around a factory writing lists of contactors isn’t fun.

Electrical equipment parameters

It’s really handy to have a copy of the factory setup parameters for anything that has them. More and more equipment these days has them- It’s not just Variable Speed Drives now- Lots of other things like optical sensors, variable pressure regulators, linear actuator controllers, inspection cameras and so on have setup parameters. Not all of these devices can be passcode protected meaning anyone on the wrong side of the Dunning-Kruger curve can have a play, get lost and cause downtime.

Sometimes this comes in the form of a backup program- for simpler devices, a paper copy is fine. Speaking of backups…

Electrical equipment backup programs

Some equipment needs a backup- PLC’s are the obvious one. Anything with a screen, generally. Some are not so obvious- Some VFD’s have so many parameters it’s impractical to program them by hand (I’m looking at you, Siemens). DC motor drives can also be very complex. Robots, their input devices and their controllers, too.

Setup procedure

The more detailed the better and remember that for this section of the manual, your audience is likely not going to be an engineer. Break the steps down as small as possible and make sure you include not just the steps to set the widget up but how you can confirm if the widget is set up correctly and use lots of pictures/diagrams. For example, let’s say we have a knife that goes into a grooved anvil and it needs to be close to the end of the groove but definitely not touching and also at the correct depth. Rather than:

“Set the knife close to the side of the anvil and the depth of cut to one milimeter”

Better to have this:

- Index the machine until indicated position 1 just before knife engages in anvil (see picture y)

- Wind side adjustment knob (item “x” in picture “y”) anticlockwise until knife is in the centre of anvil so as to ensure it doesn’t touch

- Index machine until indicated position 2 (see picture z)

- Check knife position sensor is lit up (see picture z)

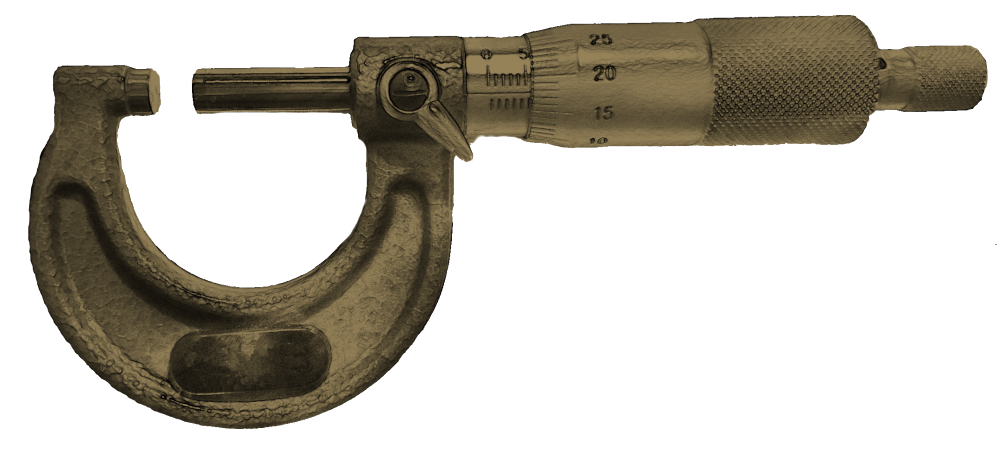

- Wind side adjustment knob clockwise until the knife is 0.3mm away from the anvil- use a feeler gauge to confirm (see picture w)

- Wind depth adjustment knob until the knife is engaged 1mm deep- use supplied gauge tool to confirm (see picture)

It can seem pretty long-winded but over time, all the people that were initially trained on the machine will leave, and not all companies have the same standard of internal knowledge transfer. If the setup procedure is particularly large, it can help simplify things to have a “full setup” procedure that the customer would use after installation or after a major service and a separate “partial setup” procedure which would be used when changing from one product to a slightly different one.

Operation procedure

Machine operation is usually well documented so I won’t dwell on this. I think as a designer, it’s pretty pleasant to explain how our creation is supposed to work. The gaps are usually in interfaces with external equipment, separate subassemblies and complex subcomponents. For example, an often neglected item is the safety system, particularly if there are multiple zones and safety controllers and especially when there are several machines linked together. This can result in two or three reset buttons having to be pushed in the correct sequence- It’s nice to have that kind of thing documented.

Maintenance information

Tell the customer everything that could possibly require attention and they can decide if it’s worth the bother. Lubrication and inspection frequency can be pretty difficult to put a realistic number on but you can start with SKF’s recommendations. In all likelihood, the customer is going to play around with these numbers a bit to fit in with their maintenance schedule; the main thing they take away from your numbers is that this bearing requires lubrication about 5 times more often than this bearing. Maintenance teams also wildly vary. If you have trouble specifying actual lubrication intervals, a list of every grease point in the plant is a really good start.

A quick list of additional things to include on your maintenance plan is below:

- Gearboxes requires oil

- Timing belts wear

- Chains requires lubrication

- Conveyor belts wear

- Coated rubber rollers wear

- Heating elements fail

- Lifting devices require inspection by a professional

- All filters need changing (pneumatic, hydraulic, water, air and anything else)

- Complex subassemblies (compressors, vac pumps, etc) should come with their own maintenance plan

- Anything hardened (knives, cams, wear plates, gears)

- Anything with a CMOS battery

With all these items, you should check with the manufacturer what the service interval is. Generally speaking though, “Lubricated for life,” is a lie and everything made of rubber will wear out. You don’t need to know how long that takes, just tell the customer to inspect it periodically.

Troubleshooting steps

I find generating troubleshooting steps to be really hard. I have a tendency to think “it’s so obvious that it doesn’t even warrant writing about,” even when it very much isn’t. From the perspective of a maintenance engineer, though, it’s never too obvious to include and I don’t find it insulting to have basic checks included. Every suggestion that you can give me is a gift.

If your PLC program is sophisticated enough that you have error codes, that’s a good place to start. For each error, think of what could cause it and put some simple steps to check those things. Nobody is expecting clairvoyance from you- The expectation is not that you have a full procedure that will result in a diagnosis in every failure.

Error 503: Knife position error

- Check the position sensor for operation and solid mounting

- Check knife shaft for compliance

- Reset position setup as per setup instructions (chapter 5)

If you designed the system, you might feel that the above steps are super obvious: Of course the knife position sensor detects the knife position and if that’s not right, you need to reset the knife position! Duh!! But for someone that doesn’t have that familiarity, you’ve communicated a lot more information than you think:

- “Knife position error” means knife position sensor error

- Either the knife position sensor or its striker is on the knife shaft

- The setup affects this

- There’s a setup procedure that you probably didn’t skip while reading this article, but you definitely did skip while skimming the 300 page tome of a machine manual.

If you’re not sure if it’s too obvious to include, it probably isn’t.

Softcopies

Ideally, anything listed above would come in both hardcopy and softcopy form.

An apology

If your equipment has Digital Input Multiplexers, hidden Remote IO’s, a combination of PNP/NPN sensors, anything password protected that you didn’t supply the password to, grease points that require tools to access or safety guards that can’t be seen through, you owe your customer one!

Conclusion

As with most machine manuals, this article ended up being larger than expected but I’ve tried as much as possible to practice what I’ve preached and have included everything that may be pertinent, no matter how obvious, condescending or overly detailed it may seem. Hopefully that has resulted in a new piece of information for you, the reader, even if you had to wade through a paragraph or two that you didn’t need. Enjoy writing your manual and remember if you aren’t sure if it’s too obvious to include, it probably isn’t.