Quickly measuring up machine covers

Working in maintenance, one of the earliest lessons I learned is to loathe opaque machine covers. Even the ones that don’t cover up critical components can cover up secrets- Leaked oil, fatigue cracks, a retrofitted PLC, who knows. And even now in the age of plastic, many machine manufacturers supply their equipment with thin sheet metal covers over equipment that needs regular inspection like universal joints and chain drives. These should be replaced with a clear cover as soon as possible to allow fast running-machine inspections. Here’s the fastest method I’ve found:

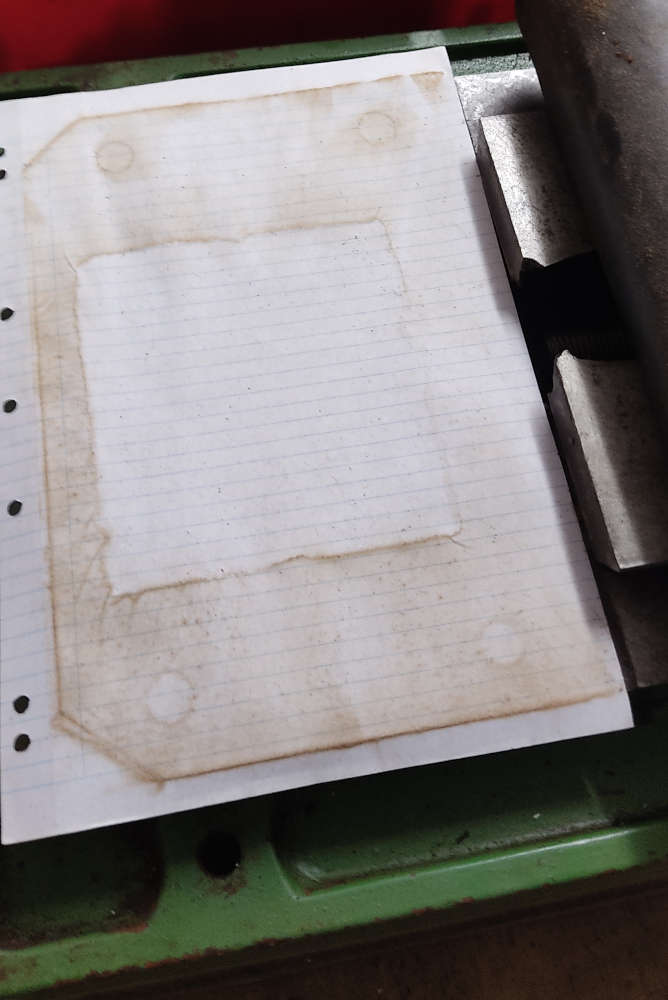

First, get a clean sheet of paper. Remove the cover if required (obviously take whatever steps are required to make this safe, LOTO, etc) and place the piece of paper over it. Hold the piece of paper on the cover and with your other hand, rub the machine and/or factory floor to get it nice and dirty. Then rub the piece of paper with your dirty hand to get the outline and replace the cover. You now have a 1:1 drawing that you can reverse engineer at your leisure. It took only 30 seconds and you didn’t even have to pick up a pencil!

Now with a drawing made, you can send out a dxf file to be laser cut. Since we’re talking about clear covers, I’ll add a note about materials- For most clear covers, polycarbonate is a better choice than acrylic for two reasons:

- Impact toughness. Polycarb is far superior in this regard, it’s the reason automotive makers use it in preference to acrylic for their headlights.

- Chemical resistance. Acrylic is susceptible to environmental stress cracking. Laser cutting seems to leave residual stress around the periphery of parts and covers like these are exposed to all sorts of solvents and oils, particularly when they get cleaned. The stress and chemicals work together and the result is lots of crazing and clouding and a cover that isn’t quite so clear any more.

May your machine inspection time forever decrease.